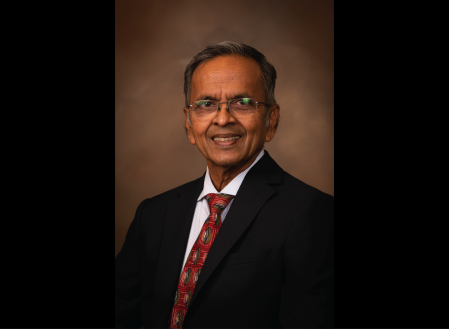

Remembering Raj Rajamani

It is with deep sadness we share with you the news of the sudden passing away of our beloved and distinguished colleague and friend, Professor Raj K. Rajamani on the late evening of Thursday, Aug 12. Raj, as he is affectionately called, was an outstanding intellectual mind. He was a highly skilled scientist, an excellent engineer, a dedicated philanthropist, and above all, one of the nicest, compassionate, thoughtful, and humble persons. Raj was a cornerstone of our Metallurgical Engineering program at the University of Utah for more than 40 years and will be greatly missed by his colleagues in the department and in our professional community.

Raj received his Ph.D. at the University of Utah and joined the Metallurgical Engineering faculty in 1979. As a faculty member for more than four decades, he was an excellent teacher and a creative researcher, and he made several significant contributions in comminution, hydrocyclone classification, and was the inventor of a new eddy current separation technology.

Raj was the pioneer in the application of the “Discrete Element Method” in the modeling of charge motion in tumbling mills and lifter design for Ag/SAG and Ball mills. He made great contributions to the computational fluid dynamics modeling of hydrocyclones and pulp lifters of tumbling mills. Notably, his research on the fundamental understanding of grinding efficiencies of overflow and grate discharge ball mills was successfully applied in the industry. He developed the first DEM code for mills called “Millsoft” in the early 1990s which led a revolution in the use of simulations for mining. In 2013 he took this further by applying the latest GPU technology with the Blaze-DEM software. In July 2021 the DEM team that he was leading received an NVIDIA inception start-up award for work on advancing automation in milling.

Most recently, his successful research included contributions on high pressure grinding and ground-breaking innovations in electrodynamic sorting (EDX) of light metals and alloys that has attracted worldwide attention and several million dollars in funding from ARPA-e/DOE. EDXTM technology for electrodynamic sorting of metals now being commercialized was his most personally satisfying contribution to society as it addressed the recycling of our key metal resources. Raj supervised the research of more than 30 graduate students over his career and was recognized for his contributions to our profession with the Antoine M. Gaudin Award presented by the Society of Mining, Metallurgy and Exploration (SME) in February 2009. The citation for his award was, “For his seminal work in the application of discrete element methods in the modeling of charge motion in semi-autogenous and ball mill grinding, and for his contribution to the basic science of comminution and classification.” Other awards include the SAG High Flyer Award in 2001 for outstanding contributions toward the development of autogenous and semi-autogenous grinding technology, the 1995 Mellow Met Award for Excellence in Teaching in the Department of Metallurgical Engineering at the University of Utah, and the 2018 Utah Innovations Award in recognition of Electrodynamic Sorting of Light Metals and Alloys (EDX). Raj made many contributions to our profession and had a great career at the University of Utah. We will dearly miss our special friend and wonderful colleague.

Whether it was metallurgy, tennis, art, or the Buddhist philosophical tradition, Raj was incredibly passionate and disciplined about mastering any endeavors he took on. Above all, his family was the center of his universe, and his contributions there far outweigh all others. As we mourn his loss, we keep Raj’s wife Sudha, and two daughters Preetha and Vidya in our thoughts.

We are in touch with the family to plan a “Celebration of Raj’s Life” event. We will share information as appropriate from the family as it becomes available.

Messages to the family can be sent to RKR.Celebration.of.Life@gmail.com. There is a card in the Dean’s Office (205 FASB) for those who would like to sign it.