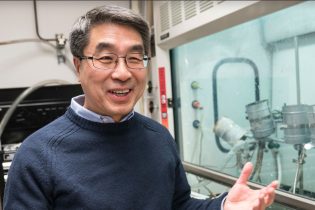

Titanium is as strong as steel—yet it’s only half the weight. So, using titanium in airplane construction, for example, would reduce fuel consumption and make flying more sustainable. Unfortunately, producing titanium is very expensive. But that is changing: Zhigang Zak Fang, U professor of metallurgical engineering, has found a way to produce high-quality titanium powder relatively inexpensively.

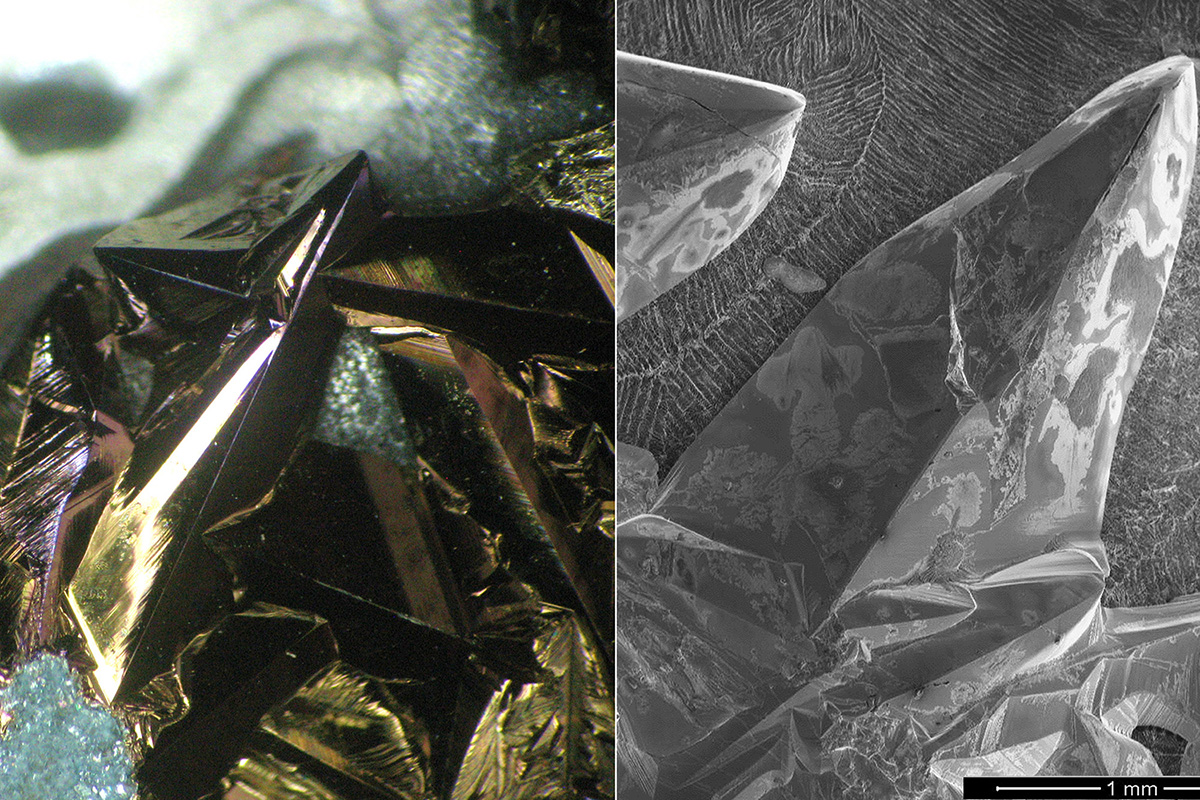

Fang developed the hydrogen-assisted metallothermic reduction (HAMR) process, which uses hydrogen and magnesium synergistically to produce the precious metal. Fang’s method also cuts carbon emissions, which creates a greener process. For that effort, and other innovations over his career—including 60 patents—Fang won the Humboldt Research Award and R&D 100 Award in 2023. “In the past, using only magnesium to create titanium didn’t work as well,” Fang says of his project, funded by the Department of Energy’s Advanced Research Projects Agency-Energy.

Under another DOE-funded venture, Fang and his colleague Pei Sun PhD’15 are looking for a new way to produce iron and steel that will use less energy and release fewer emissions. “The goal is to decarbonize the steelmaking industry,” Fang says.

Read Article in University of Utah Magazine HERE

https://magazine.utah.edu/issues/fall-2024/innovation-university/